|

Welcome to all those who have recently signed up for our

free email newsletter!

Part 5

- What's All The Talk About Electronics?

What

do I need to know? What do I need to do?

Back in Part 3 we asked

these questions and some insight. In Part 5 we will answer the first two

questions with more specifics.

What do I need to know

about electronics now that computers are involved?

What level of training

do I need in electronics?

By the way, stay

connected to our email newsletter list. We will very soon announce by email

a new web site where vehicle service technicians can access our 60 lesson

training program called "The" Vehicle Electronics Training

Program for on-line study.

For now, let's discuss

what technicians should do about vehicle electronics training in today's

vehicle industry. We have seen dramatic changes in electronics in just the

last two decades. One area specifically is construction of PCBs (printed

circuit boards). Electronic components have become more miniaturized than

ever before allowing complex electronic circuits to be created in smaller

packages. This makes circuit boards much smaller and less expensive to

produce, but practically impossible to repair by human hands. They are

simply too small. Although very advanced PCBs are very difficult to repair,

they have created a revolution in electronics training.

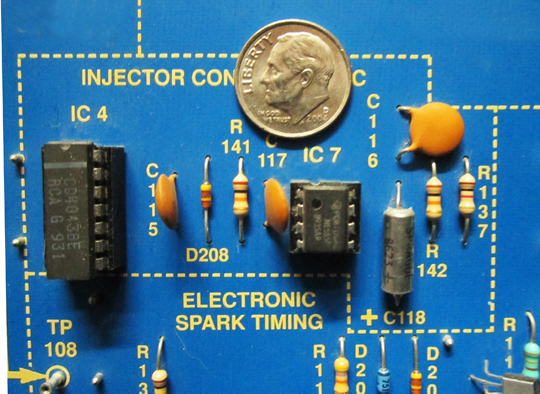

Here

are some examples of what I'm talking about. The first illustration in

Figure 1 shows the electronic component size found in vehicle on-board

control units in the late 1980's compared to a 10 cent dime.

Fig. 1

Electronics

components mounted on an old style PCB

Notice the size of the

fixed carbon resistors, they are the components mounted vertically with

painted color bands indicating their resistance value. The light orange

disc capacitors with two leads lying flat at the top right, the other two

mounted vertically compared to a dime are easy to replace by hand if

needed. There are two integrated circuits large enough to be de-soldered

and a new IC installed, if needed. It is also possible to measure the

voltage or the waveform with the lab scope on any of the pins of an IC that

are physically this large.

The size of these

components are quite easy to handle by human hands and a needle nose

pliers. The components can be inserted into the circuit board and soldered

in place with little trouble and average eyesight. Also consider how large

the size of the circuit board and how heavy it would be containing a

complete circuit consisting of several ICs, power transistors, multiple

resistors and capacitors.

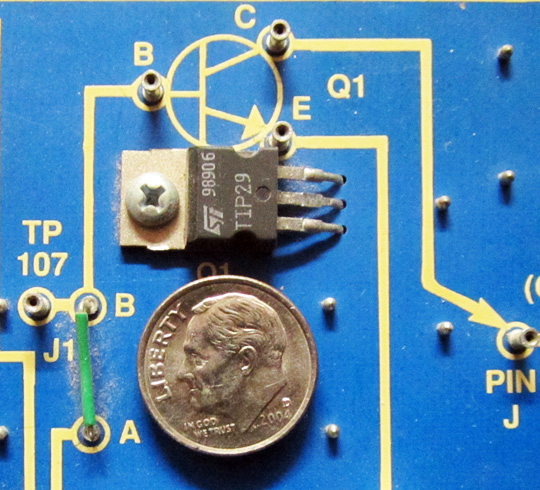

Fig. 2

Power Transistor mounted

on a PCB

The power transistor is almost as large as a dime. An

electronic technician would be trained in electronics school to test the

transistor with the proper type of ohmmeter and look for a bad internal

transistor junction. He would also be trained in an electronic school to

measure the voltages and waveforms on the appropriate transistor leads.

If the transistor is

found to be defective, the three transistor leads can easily be de-soldered

from the circuit board. Remove the mounting screw, de-solder the three

leads, remove the transistor, insert a new transistor, install the mounting

screw, and re-solder the three leads. This would be a simple task for an

electronics technician with a soldering iron and needle nose pliers. This

was common PCB repair in the old days. Printed circuit board

technology has come a long way in the last 25 years.

In Figure 3 below, we

see a photograph of a modern day computer printed circuit board. Notice the

small size compared to the size of a 10 cent dime and the rows of tiny

"chip" resistors and other circuit components.

Fig. 3

Small electronic component

size compared to a 10 cent coin

Measuring voltage and

waveforms at the smaller IC pins is more tedious than before. The probe tip

could easily short two pins together and possibly destroy an IC.It has

reached the point where the circuit boards contain miniature components

that are almost impossible for a human to replace. I can tell you from personal

experience trying to repair these new circuit boards with "chip"

components when they first began to arrive in vehicles in the late 1980's,

was a nerve racking experience. Trying to replace one of those tiny

"chip" components and solder it at both ends while holding it in

place with a needle nose pliers took patience and skill. It did not take

long for manufacturers to realize these tiny "chip" components

could not be replaced by human hands.

As a result of this

change in electronic component size and PCB construction, the training

required of technicians to repair circuit boards began to decline. Vehicle

manufacturers decided to replace defective control units with new ones

rather than have them repaired by electronics technicians. Today, most

onboard computers, due to this new PCB technology, are replaced rather than

repaired. This also affects other segments of the electronics industry. One

example, if your home/office PC develops a problem on the motherboard, it

is more economical to buy a new motherboard rather than attempt to repair

the old motherboard.

Therefore, schools that

taught electronics for circuit board repair down to the component level

began closing down due to low student enrollment. There is a declining need

for electronic technicians with skills to repair circuit boards in today's

technology. As a result, many of the electrical and electronic

troubleshooting skills that were taught in electronic schools in the past

is being lost. They are not being passed on to the next generation. Some of

these skills would be helpful for a vehicle service technician to test a

vehicle electronic system.

For example, the

technique of testing a transistor with an ohmmeter is being lost. Of

course, a service technician today would never be expected to test and

replace a transistor in an onboard computer. But knowing how to test

solid-state components like transistors and diodes with an ohmmeter can be

adapted in other areas of vehicle maintenance. This skill could be used to

test L.E.D. lamp assemblies and some sensors containing solid-state

components. I could cite several examples but due to the length of this

article I only want to address one.

A few months ago I was

conducting an electrical - electronics training class in a fleet

maintenance shop. The technicians in the class mentioned they were having

trouble with an emergency flashing light unit mounted on many of their

vehicles. Some vehicles would have two or four of these units mounted on

the vehicle. They would last about six months then they would have to be

replaced at almost $200 a pop. We disassembled one of the defective units

and on the circuit board was a power transistor. I tested it with my

ohmmeter and saw that it was bad. It would have been a simple task to

de-solder the defective power transistor and install a new one to repair

the unit. The cost to repair by replacing the power transistor would have

been less than $20 and taken 10-15 minutes.

Let me say this loud and

clear. I do not recommend, nor do I imply a vehicle service technician ever

open up an on-board computer and attempt to repair the circuit board. These

emergency light assemblies with solid-state components are a different

matter and perfectly safe to look inside and repair. But NEVER do that with

an on-board vehicle computer.

Today it is more

economical to replace an on-board control unit rather than train and pay an

electronics technician, provide an expensive electronic repair workstation

to repair the original circuit board when it develops a problem. It is

cheaper in most cases to build new on-board control units rather than

repair old ones. So many manufacturers ask why continue to train electronic

technicians to repair computer circuit boards down to the component level

when a brand-new unit can be manufactured at less expense?

I think we can all agree

with that decision, but let's not overlook the need for the proper

electrical - electronics training to help a service technician make the

decision that the problem is inside the computer or something in the

vehicle circuit has caused the computer failure. Let's eliminate the

guessing game that the on-board computer is bad or the problem is in the

vehicle circuit.

What do I need to know

about electronics now that vehicle computers are involved?

Today's vehicle

electronic technician does not have to study in depth electronics theory to

be able to repair computer circuit boards. For example an electronics technician

is taught to calculate the inductive reactance in ohms of a coil in a

circuit at a specific frequency. He is taught to calculate the capacitive

reactance of a capacitor in ohms in a circuit at a specific frequency.

Neither exercise would be of benefit to a vehicle service technician. So we

can dispense with this in-depth level of electronic training for a vehicle

service technician. What is really needed is a training program that

specifically addresses the skills to handle the electronics level of diagnosis

and repair the vehicle service technician faces with today's vehicle

technology.

What level of training do

I need in electronics?

A vehicle service

technician does not have to become an electronics technician but should

have a clear understanding of the principles of series and parallel

circuits. How circuits work, how circuits fail and how to electrically

troubleshoot any circuit on any vehicle should be the main focus of

hands-on training. A vehicle service technician should understand the DMM and

Current Clamp, not just in theory, but in practical application from

effective hands-on troubleshooting training exercises.

He should understand

technical subjects such as the workings of a coil in a DC circuit and what

parameters he should be concerned with if the coil is controlled by an

expensive on-board computer, such as spike voltage protection. He should

understand the importance of capacitors in DC circuits. This would be

beneficial to vehicle service technicians dealing with hybrid vehicles

employing "ultra-capacitors."

This is the ultimate

goal of electrical electronics troubleshooting training for vehicle service

technicians. The training should encompass hands-on troubleshooting

techniques that allow a technician to perform circuit tests to reveal

circuit problems even when service information is not available and the

technician has little or no previous knowledge of the circuit. This may

sound like a tall order but this level of electrical-electronics

troubleshooting training is available right now.

Visit our web site for

all the details about our electrical-electronics training programs that

address these issues and more. These three links will help you navigate our

main website.

If you are a service

technician click here.

If you are a shop owner click here.

If you are a teacher click here.

These links will explain

our various training programs and give you direction on how to proceed.

If you are interested in

the 60 lessons and would like more information about

"The" Vehicle Electronics Training

Program click here.

Stay connected to our email newsletter list. We will very soon

announce by email a new web site where vehicle service technicians can

access our 60 lesson training program called "The" Vehicle Electronics Training

Program for on-line study.

Technicians will study

the lessons online and print out their own lessons if they wish. We will be

offering a lifetime membership to this website. We also are planning some

exciting additions to the 60 lesson home study course that will also be

provided over time. We will let you know as soon as this website is posted

on the Internet and ready for enrollment.

The next installment,

Part 6, we will answer some of the following questions.

How do I test a driver

transistor circuit?

What is required testing

a vehicle computer?

If the circuit doesn't

work, how do I tell what is the reason for the failure?

Is the problem in the

computer or a problem in the vehicle circuit?

Can a computer circuit

fail because there is a problem in the vehicle that will cause the new

computer to fail after I replace it?

What do I need to do to

increase my electronics knowledge without over kill?

How much electronics training is enough?

Look

for our special announcement.

Vince Fischelli

Director of Training

Veejer Enterprises

Web site: www.veejer.com

Email: vince@veejer.com

Phone: 972.276.9642

Fax: 972.276.8122

|